Call Now (800) 879-1964

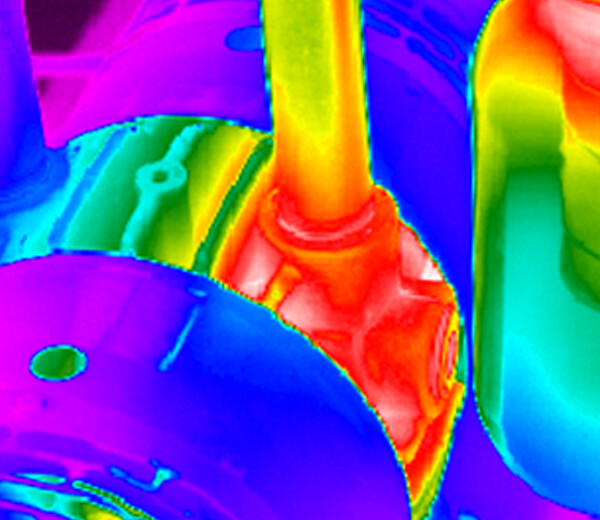

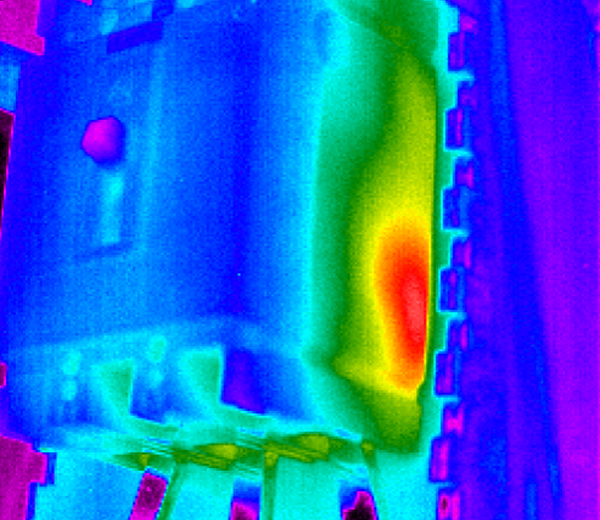

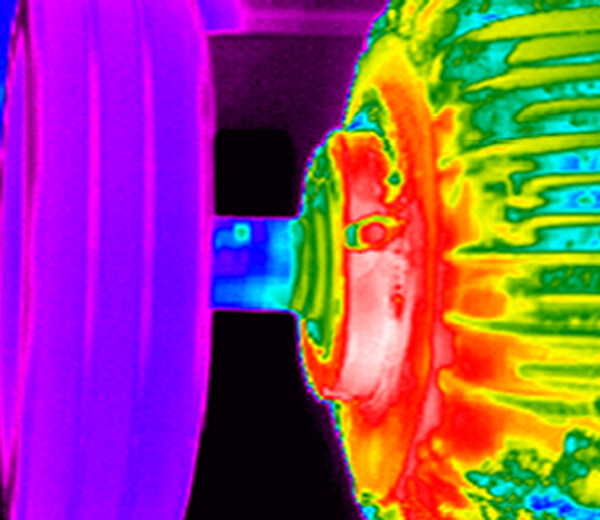

Our state-of-the-art infrared technology allows us to identify issues in your electrical and mechanical systems without disrupting your operations. This proactive approach helps you avoid unscheduled maintenance, reduce downtime, and significantly improve your facility's efficiency and safety.

Because our thermography is non-contact and non-destructive, there's no need to interrupt production or plan for costly shutdowns. We inspect your equipment under normal loads and operating conditions, allowing you to:

With our electrical and mechanical Inspections, you're not just preventing failures—you're investing in your facility's long-term performance and profitability. You gain insights that can lead to significant cost savings, improved safety, and extended equipment lifespan.