Call Now (800) 879-1964

In commercial buildings, water can seep silently into roofing and wall systems, causing significant damage long before any visible signs appear. The longer it goes undetected, the more it costs in repairs, downtime and liability. That's why Infrared Moisture Surveys are so valuable.

At IR Analyzers, we use non-destructive infrared technology to quickly, accurately and inexpensively locate hidden moisture damage without major invasive exploration. It's a critical tool in helping all industry stakeholders proactively address small problems before they become larger and more expensive.

In this post, we will explain how thermal imaging moisture scanning works, when to use it, and why early detection has huge benefits.

Water travels through the building envelope both horizontally and vertically, typically showing up far from the original entry point. This makes it very difficult to trace the true source of a leak using visual inspections alone.

In commercial buildings, the challenge is even greater. Roof assemblies and wall systems are often composed of multiple concealed layers—insulation, membranes, decking, and finish materials—all of which can conceal signs of moisture.

By the time the leak shows up inside the building, moisture damage is often widespread and costly.

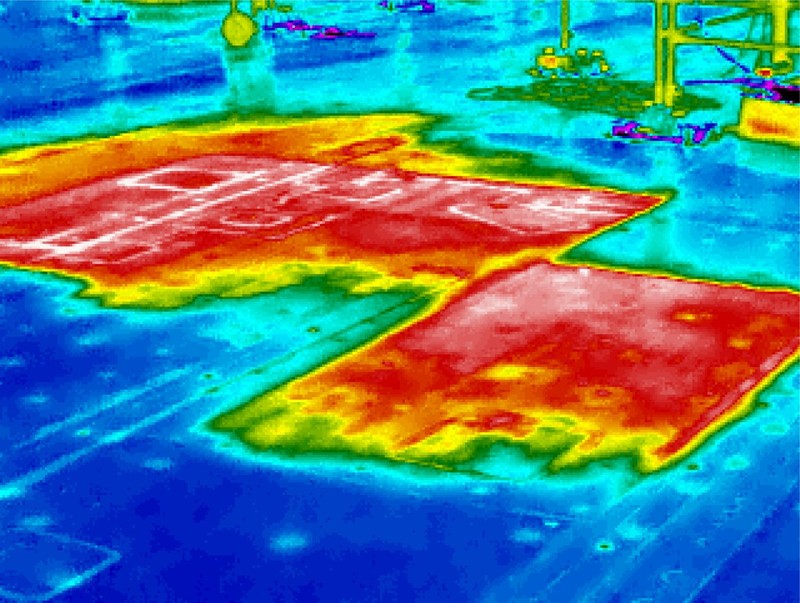

Thermal imaging uses high resolution infrared cameras to detect temperature difference across the roof or wall surfaces. The cameras capture subtle heat images that aren't visible to the naked eye. These high quality “heat pictures” make it possible to identify moisture issues quickly, and large areas can be inspected very cost-effectively.

In building diagnostics, fast and accurate thermal imaging is employed to assess critical assets such as commercial roofs and exterior walls for hidden moisture or insulation issues without the need to open up the structure.

For example, Infrared Roof Moisture Surveys can identify areas of water damage beneath the roofing membrane. This allows for fast, precisely targeted assessments and repairs without significant invasive exploration.

In Building Envelope Testing, infrared imaging will assess cladding, facades, windows, and doors to isolate areas of moisture damage.

It is important to understand that Infrared Testing alone will not provide thorough and accurate survey results on many roof assemblies. To conduct comprehensive non-destructive moisture assessments, many roofs will require a combination of specialized techniques. We typically supplement Infrared Testing with Nuclear and / or Capacitance Testing in areas where the infrared imagery is inconclusive or unreliable. By combining technologies, we are able to inspect 100% of the roofing quickly and accurately.

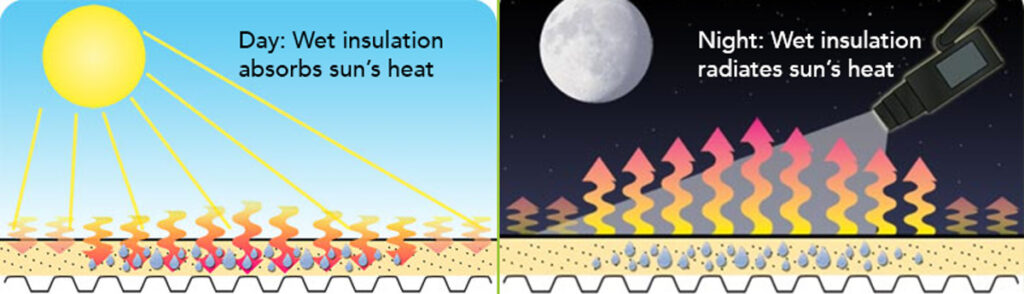

Infrared testing is performed in the evening, after the roof has absorbed daytime solar heat. At night, the wet insulation releases this stored heat, creating distinct warmer and cooler thermal patterns that indicate the difference between wet and dry insulation.

Non-destructive thermal imagery proactively flags areas of moisture damage that would not be found during visual inspections.

When water intrusion goes undetected, small problems can quickly escalate into major repairs or replacement, compromising structural integrity, disrupting operations, and increasing liability. Thermal imaging helps prevent those costly outcomes by identifying issues early, before they spread.

Here's how thermal imaging supports proactive maintenance and enables smarter and more cost-effective repairs:

Thermal imaging allows large areas to be scanned quickly and cost-effectively, especially when combined with other moisture detection techniques. Problem areas are pinpointed for repair or replacement, substantially reducing overall maintenance costs.

Invasive sampling only provides accurate information at the exact site of the core cut. Random sampling with core cuts leaves the vast majority of the roof untested, while Infrared Roof Moisture Surveys can provide 100% surface coverage when combined with Nuclear or Capacitance Testing as needed. Comprehensive Non-destructive Testing ensures repairs are based on accurate data, not guesswork.

Thermal imaging highlights the true locations of moisture damage, which can’t be determined with visual inspections alone. This focuses remediation efforts exactly where they are needed, reducing repair costs, preserving intact materials, and avoiding scope creep.

In many cases, early detection leads to smaller, localized repairs, rather than large-scale replacements.

At IR Analyzers, our team of 10 experienced Technicians allows us to complete Infrared Roof Surveys quickly, with minimal need for site support. This reduces schedule disruption and workforce impact.

By aligning with ASTM C1153, our thermal imaging reports provide unbiased, trusted, third-party validation. They can support insurance claims, warranty coverage, and internal documentation, reducing exposure to liability and helping justify repair decisions with confidence.

Thermal imaging is most effective when it's used proactively, not just after leaks or water damage become visible.

Here are a few situations where thermal imaging is especially valuable:

Regularly scheduled inspections help identify early-stage moisture issues before they negatively impact building performance or require extensive remediation.

High winds and heavy rain can seriously compromise roofing systems and wall assemblies. Our thermal scans provide non-invasive water damage detection, pinpointing problem areas quickly and accurately, and avoiding unnecessary repairs.

Our Infrared Moisture Surveys provide unbiased third-party documentation of problems and are backed up with comprehensive, industry-leading reports.

By using thermal imaging in these scenarios, facility teams and building owners can make more informed decisions, catch problems early, and avoid the high costs that come with delayed repairs.

An Infrared Moisture Survey provides a clear picture of the building envelope’s condition, supporting transparency and reducing surprises during and after negotiations.

Thermal imaging is fast, accurate, and non-destructive, but its greatest value lies in how early it can detect problems. Moisture trapped inside a roof or wall system doesn’t just dry out on its own. Left unchecked, it spreads, compromising insulation, corroding materials, and increasing the scope and cost of repairs.

Early detection is the difference between a targeted repair and a full system replacement.

With over 40 years in the field and more than 30,000 completed surveys, IR Analyzers brings unmatched experience to each project. Our team includes ASNT-certified technicians, and our methods align with ASTM C1153, ensuring that every scan delivers reliable, standards-based results.

Don’t wait for visible damage. Protect your building now before the repairs get expensive.