Call Now (800) 879-1964

When it comes to protecting a commercial roof, what you can’t see can cost you. Moisture

trapped beneath the surface often goes undetected until it causes serious problems, damaging

building contents, disrupting operations, voiding warranties, and accelerating system failure.

That’s where nuclear testing comes in.

A Nuclear Moisture Gauge provides non-destructive, highly accurate detection of hidden

moisture within roofing assemblies. Unlike infrared scans that rely on surface temperatures,

nuclear testing measures the amount of hydrogen in the assembly. Once baseline hydrogen

values are established for dry materials, elevated hydrogen levels typically indicate increasing

amounts of water damage (H2O) and uncover water intrusion that other methods might miss.

In this guide, we’ll break down how nuclear testing works, when it’s the right tool for the job, and

how IR Analyzers uses this technology to help clients make confident, data-backed decisions

about their roofing systems.

The Troxler® 3216 Nuclear Roof Moisture Gauge is an extremely sensitive and accurate

instrument for determining the locations and extent of moisture damage in insulated roofing

systems. In the context of commercial roofing, it allows our technicians to assess the condition

of insulation and other materials that may be holding hidden moisture.

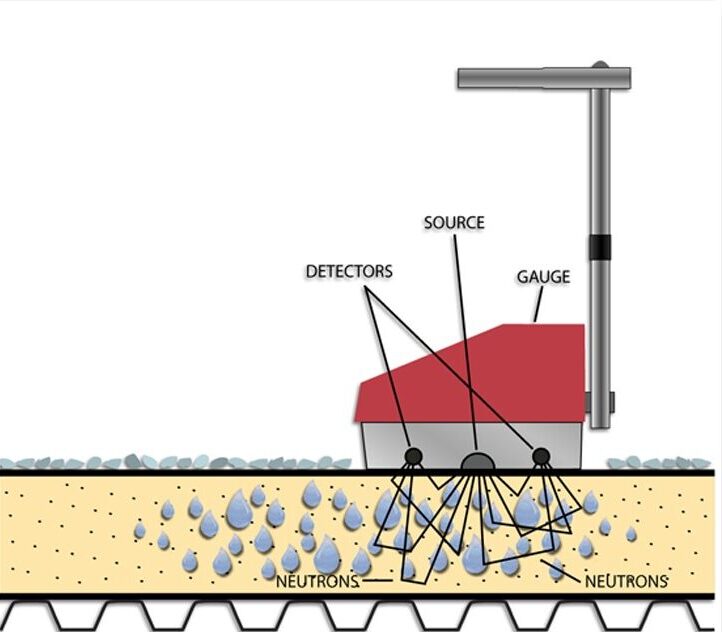

The instrument works by emitting low-level radiation from a sealed source into the roofing

materials. Sensors then detect how that radiation interacts with the material, allowing us to

locate and document the moisture content with a high degree of accuracy.

A nuclear moisture gauge works by emitting low-level gamma radiation from a sealed radioactive source Americium-241:Beryllium - within the unit.

By employing a principle called neutron moderation, these tiny radioactive releases detect hydrogen

ions, and provide a count of how many hydrogen atoms there are in the assembly. Neutrons emitted

from an isotopic source collide easily with the highly exposed neutrons of hydrogen, and these

collisions slow their travel. By detecting changes in the speed of the emitted neutrons, it is possible

to quickly, safely, and accurately identify moisture in the roof.

It is important to understand that the gauge is actually counting the number of hydrogen atoms

in the assembly. Because other hydrogen bearing materials are present in roof structures, it is

critical to establish a relative base level or gauge reading that indicates dry materials. Areas

showing a higher than normal moisture count can then be determined to contain varying

amounts of moisture.

All Roof Moisture Survey techniques utilize technologies that measure a characteristic of the

assembly that can then be interpreted as moisture damage, but does not directly identify the

difference between wet and dry materials.

Infrared Roof Surveys pinpoint moisture through the interpretation of thermal anomalies on the

roof surface. When the conditions are set up correctly, areas of moisture damage will manifest

as warmer anomalies on the roof surface versus cooler patterns of dry insulation. Capacitance

Testing utilizes electrical currents to measure electrical flow through the materials. Moisture can

be detected because moisture-damaged materials will have less electrical resistance and

conduct the current more rapidly.

It is very important to understand that the nuclear gauge is also not directly measuring moisture.

It is sensing the amount of hydrogen in the system. All hydrogen in the assembly will register on

the gauge. Certain assemblies like single-ply membranes (TPO, PVC, EPDM, etc.) over cover

boards and insulation will have relatively small amounts of background hydrogen in dry

materials and therefore lower hydrogen baselines. However, hydrocarbon-based assemblies

containing asphalt or cold tar pitch can naturally contain significantly more hydrogen, resulting in

background (dry) counts that are typically higher.

In addition, single-ply membrane assemblies are typically quite homogeneous regarding the

amount of baseline hydrogen. However, with asphaltic and cold tar pitch assemblies, there are

often greater variations in material thickness, and the background levels of hydrogen will vary

accordingly. These assemblies can present readings that are more challenging to interpret, as

higher readings might represent greater amounts of hydrogen-containing materials rather than

moisture damage. These concerns can be largely mitigated by employing experienced Certified

Technicians who are able to calibrate the gauge with selective invasive testing (core samples).

Although this technology is commonly used in soil compaction testing, its application in roofing is tailored to evaluating insulation health and waterproofing integrity. Here’s how the procedure typically unfolds in the field:

Nuclear data points are measured and marked on the roof on a grid, typically with 10 ft

intervals on the X and Y axes. Some surveys are conducted with 5 ft intervals or even 3

ft by 3 ft intervals, depending on the size of the roof, and the desired degree of

granularity.

The nuclear gauge is placed directly on the membrane, and the hydrogen count of the

roofing materials is measured and recorded. Nuclear Roof Moisture Surveys are typically

conducted on a 10’ x 10’ grid pattern across the entire roof surface. On ballasted roofs,

the rocks will be temporarily moved aside in order to place the nuclear gauge directly on

the roof surface. Readings are taken at each grid intersection to create a hydrogen

profile of the roof system.

The gauge emits gamma rays into the roofing system. Based on the characteristics of

the backscattered radiation, the system calculates actual hydrogen counts and flags

areas likely to contain moisture. Ideally, selected core samples are employed to calibrate

the gauge and absolutely determine the presence or absence of moisture. If it is not

possible to cut core samples (warranty issues, owner restrictions, etc.), estimations will

have to be made as to the significance of the numbers, higher and lower. If no physical

core sampling is done to establish ground truth conditions, the findings will be presented

as suspected or probable areas of moisture damage.

Hydrogen Baselines: To accurately analyze the data from this sensitive nuclear

detection technology, we must account for the original hydrogen content of dry roofing

materials. By utilizing small amounts of invasive testing, hydrogen readings can be

established for dry materials. After dry material baselines are established, elevated

hydrogen counts typically indicate moisture damage in the roof system.

Ideally, core sampling can be performed to establish dry reading baselines and verify

moisture in areas with elevated hydrogen counts. This empirical approach will greatly

enhance the reliability of the testing. In situations where it is not possible to perform core

sampling of the assembly, the hydrogen baselines must be estimated, and elevated

readings will be assumed to represent moisture damage.

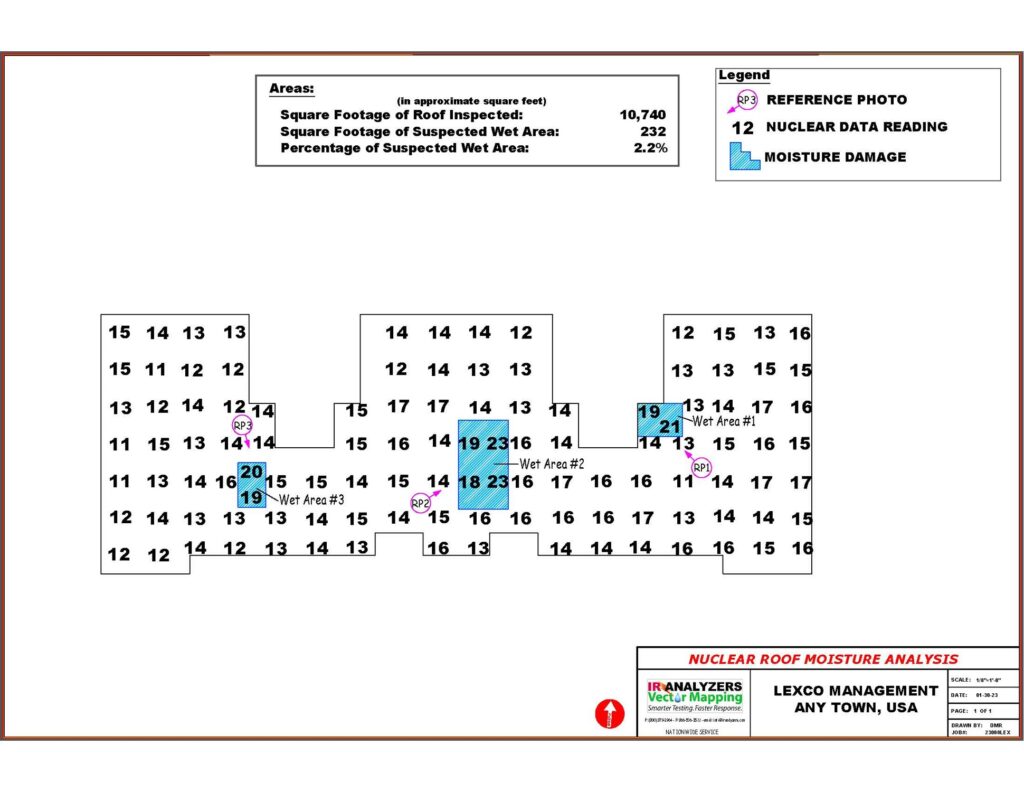

A comprehensive report is compiled and submitted that details the test procedures,

locations and findings of any invasive testing, and AutoCAD drawings of test results

including grid layout, hydrogen counts, locations of moisture damage, and percentages of

wet and dry materials.

Before, during, and after the survey, the unit is stored, transported, and utilized in

accordance with all federal and state regulations.

Possessing and operating nuclear moisture gauges requires licensing and certification

by federal, state, and occasionally local authorities. To eliminate risk on the part of our

company and our customers’ companies, IR Analyzers always conducts the testing in

accordance with all applicable authorities.

All IR Analyzers Certified Technicians:

These procedures ensure that nuclear testing is conducted safely, not only for our team but for building occupants, site personnel, and the environment.

Nuclear density gauges are one of the most precise tools available for detecting hidden moisture in commercial roofing systems. At IR Analyzers, we deploy this technology to conduct our Nuclear Roof Moisture Surveys, when conditions call for deeper insight than visual inspections or infrared scans can provide.

While not every project requires nuclear testing, there are several situations where it's the most appropriate—and often the most effective—choice.

Our technicians typically recommend Nuclear Roof Moisture Surveys in scenarios like:

Unlike Infrared Surveys, Nuclear Testing can be relied upon to produce highly accurate

information on reflective membranes (cool roofs).

Nuclear Testing is the only reliable technique for determining the locations and extent of

moisture damage in ballasted roofing systems (covered in 1 -1.5” river rock).

Nuclear has the advantage of being able to read much more deeply into a roof assembly

than the infrared camera. This can be very beneficial in multi-layer systems, or when

there is concern about moisture near the bottom of the system, especially if it is present

under dry insulation.

Nuclear surveys do not rely on the sun’s heat to warm the wet insulation, so Nuclear

Testing provides excellent information in shaded areas, ensuring that 100% of the roof

assembly is tested.

After major weather events, nuclear testing helps verify the true condition of the

assembly, often a requirement for warranty claims or insurance documentation.

For property acquisitions, condition assessments, or budgeting major repairs, due

diligence Nuclear Moisture Surveys give you the comprehensive and accurate

information needed to make data-driven decisions that save time and money.

If you're considering a Nuclear Roof Moisture Survey, you're likely asking: What will the results tell me, and how will they help me make the right decision for my roof?

This test is designed to detect and quantify moisture within roofing systems. After the test, you’ll

receive a detailed report that includes:

These results help you understand whether you're dealing with isolated wet areas or more

serious moisture damage.

Your test results are decision-making tools. With these insights, you can:

At IR Analyzers, we focus on providing objective reports that are designed to be clear, actionable, and aligned with industry standards, so you can confidently make decisions about your roof system.

When it comes to identifying hidden moisture in commercial roofing systems, precision and

experience matter. IR Analyzers has been at the forefront of non-destructive roof testing for over

40 years, with a reputation built on technical expertise, reliable data, and responsive service.

Every Nuclear Roof Moisture Survey is performed by licensed professional Certified

Technicians trained in both radiation safety and advanced testing procedures. Our technicians

bring unmatched knowledge to every project, ensuring accurate testing and clear interpretation

of results.

Whether you need to confirm roof conditions, support a warranty claim, or plan critical repairs,

our Nuclear Roof Moisture Surveys give you the insight you need accurately, safely, and on

schedule. Because of the accuracy and reliability of Nuclear Moisture Surveys, billions of

square feet of roofing have been safely and accurately analyzed with nuclear testing.

Ready to schedule your survey? Contact our testing team today.