Call Now (800) 879-1964

Hidden moisture inside a roof system is a silent threat. Over time, trapped water can damage insulation, corrode decking, and lead to premature failure, resulting in costly repairs or replacement.

Unfortunately, moisture problems typically aren’t visible from the surface, and that’s when Non-Destructive Roof Moisture Testing becomes essential.

We will discuss two proven approaches—Infrared and Nuclear Roof Moisture Surveys—that help building owners, contractors, and facility managers detect hidden issues early. This guide explains how each method works, their strengths and limitations, and how to decide which approach best fits your testing needs.

Which test type is best for your building? As is often the case with non-destructive roof moisture testing, there is no one simple answer.

Both Infrared and Nuclear Roof Moisture Surveys have helped pinpoint hidden moisture across billions of square feet of roofing. Each technique uses a different principle to locate trapped water and has distinct advantages and limitations.

Because no method is perfect, it is critically important to understand the potential for each to generate false positives (indicating moisture damage in areas that are actually dry) and false negatives (failing to detect areas where moisture is present).

The sections below explain how each method works and how to get the most out of each technique.

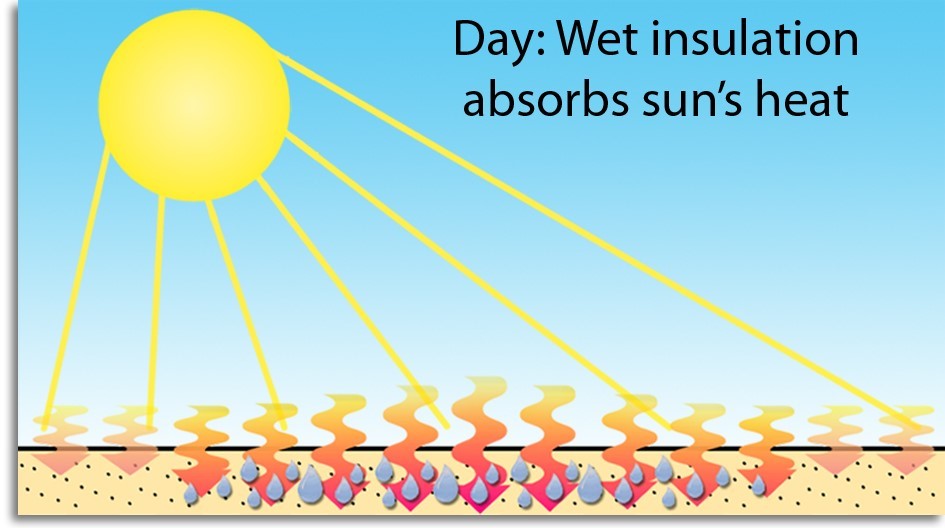

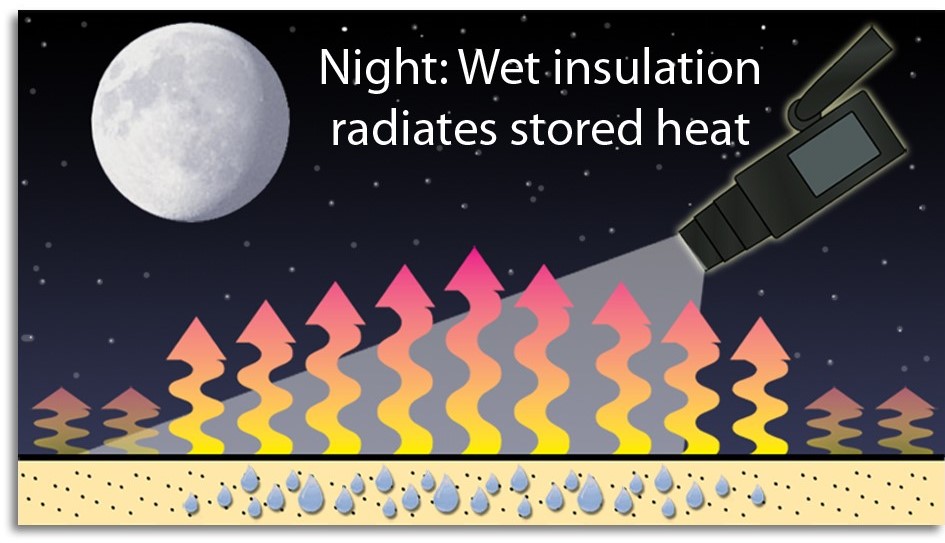

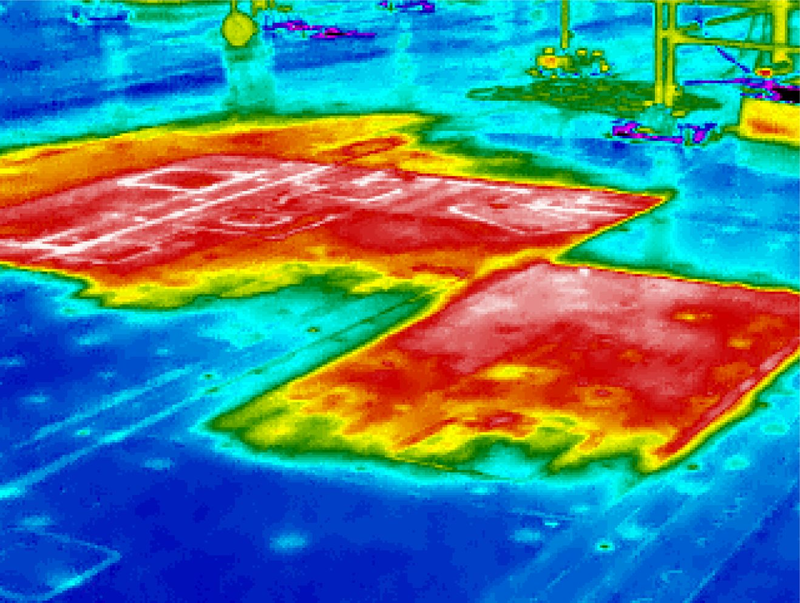

Infrared Roof Moisture Surveys pinpoint moisture-damaged areas by creating a thermal image of the roof surface. During the day, wet insulation absorbs more solar energy. At night, these saturated areas retain heat longer than surrounding dry areas, appearing as bright “hot spots” to the infrared camera.

Because infrared scanning can cover large areas quickly and inexpensively, it’s often considered the go-to for initial surveys and periodic monitoring.

Here’s a closer look at what makes Infrared Testing effective (and also where it can fall short).

Infrared Testing has several important limitations:

Because of these restrictions, Infrared Surveys must be planned carefully and performed under optimal conditions to produce reliable results. In addition, it is often necessary to supplement or cross-check the infrared imagery with Nuclear or Capacitance Testing in selected areas to produce accurate results across the entire roof surface.

Infrared Roof Moisture Surveys are a good choice when:

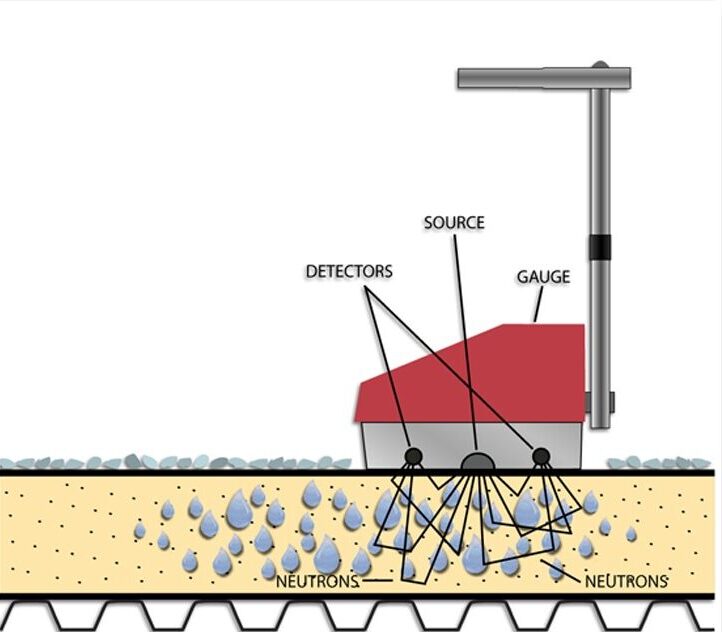

Unlike infrared moisture detection, Nuclear Testing does not rely on surface temperature changes. Instead, it measures hydrogen content inside the roof system using neutron moderation.

A nuclear gauge emits fast neutrons that slow down when they collide with hydrogen atoms (found in water). The detector counts these moderated neutrons to establish moisture content.

Nuclear Roof Moisture Surveys can detect moisture deeper in the roof assembly—even under dry insulation—and work in a wide variety of weather conditions.

Here’s a closer look at what makes Nuclear Testing effective (and where it can fall short).

While nuclear testing is very sensitive and accurate, it has some important constraints:

Consider Nuclear Roof Moisture Testing if:

It’s important to note that neither infrared nor nuclear methods measure moisture directly. In Nuclear Testing, gauges measure hydrogen atoms in the roof assembly. All hydrogen will register, whether it comes from water or naturally hydrogen-bearing materials.

Different roofing materials have different background hydrogen levels. For example:

This is why establishing accurate baseline readings—often with core samples—is essential. Referencing higher readings to established dry areas helps technicians determine where elevated counts truly indicate moisture.

When reviewing proposals or reports, it helps to understand how Nuclear Gauges work:

At IR Analyzers, we use Troxler® 3216 Nuclear Roof Moisture Gauges. They are one of the most sensitive instruments available. It is portable and accurate and an excellent tool to create moisture profiles that inform better decision making for targeted repairs or replacements.

Whether you choose Infrared or Nuclear Roof Moisture Surveys, the procedure follows a structured process:

1. Survey Planning: The IR Analyzers team assesses roof conditions, selects the appropriate method (or methods), and plans the testing procedure.

2. Field Procedures:

3. Baseline Establishment: For both Infrared and Nuclear Surveys, the most accurate results are achieved by using selective core sampling to establish ground truth wet and dry conditions.

4. Data Analysis: Readings are compared to baselines to identify suspect areas.

5. Report Submission: Survey results are generated that establish the true moisture conditions to assist in making better decisions, saving time and money.

Both Infrared and Nuclear Roof Moisture Surveys are proven and valuable tools for identifying hidden moisture that can compromise the performance and longevity of roofing systems. Each method offers distinct advantages and limitations depending on the roof’s construction, environmental conditions, and the specific objectives of the assessment.

By understanding how these techniques work and the factors that influence their accuracy, building owners and professionals can make better informed decisions about which approach—or combination of approaches—best supports their maintenance and asset protection goals.

Every roof is unique. The right testing approach depends on your roof assembly, site conditions, and maintenance goals.

If you’d like help deciding between Infrared and Nuclear Surveys—or when to combine them or even utilize Capacitance Roof Moisture Testing—contact us today. Our experienced specialists will recommend the most effective way to identify hidden moisture damage and protect your investment.