Call Now (800) 879-1964

Electronic Leak Detection (ELD) is often used during the roof construction phase, as an integrity/acceptance test post-construction, and for investigating known or suspected leaks. It is vastly superior to flood testing when pinpointing leaks and breaches in waterproofing membranes.

However, there are different types of ELD, and it’s important to choose the right method based on your roof assembly and its history. Some roofing assemblies (or sections of an assembly) respond better to dry testing with High Voltage ELD, while others are better suited to wet testing with Electric Field Vector Mapping.

In addition, many roofs include conditions that call for both. In this post, we break down how each method works and where each one excels at providing the most thorough and accurate testing.

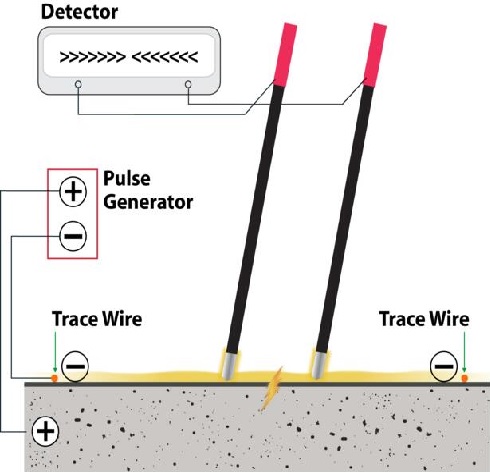

Electric Field Vector Mapping is a low-voltage ELD method often referred to as "wet testing." To perform Electric Field Vector Mapping, the technician first lays out a conductive boundary wire (trace wire) around the area to be tested (test bed) and applies a low amperage 40-volt DC current.

The membrane surface is lightly moistened, allowing the electrical current to spread across the test bed. Using two sensor poles and a potentiometer, the technician tracks the direction of current flow to pinpoint where it travels through a breach and grounds—revealing the exact location of membrane failures.

Electric Field Vector Mapping is especially well-suited for testing large, open roof areas. When the surface is accessible and unobstructed, Electric Field Vector Mapping can deliver clear and reliable results across broad sections of the field of the membrane.

Because Electric Field Vector Mapping relies on moisture to conduct current, it has some limitations, especially around complex detailing:

These limitations can make Electric Field Vector Mapping less effective in areas with metal or numerous penetrations, obstructions, or vertical elements—roof sections that may require a complementary testing method.

Electric Field Vector Mapping

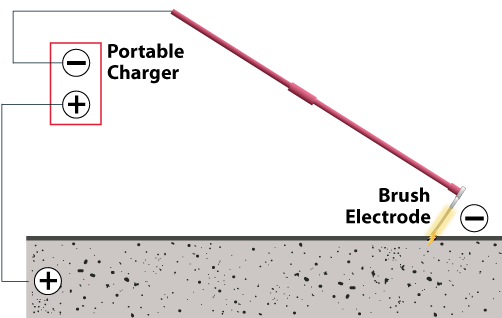

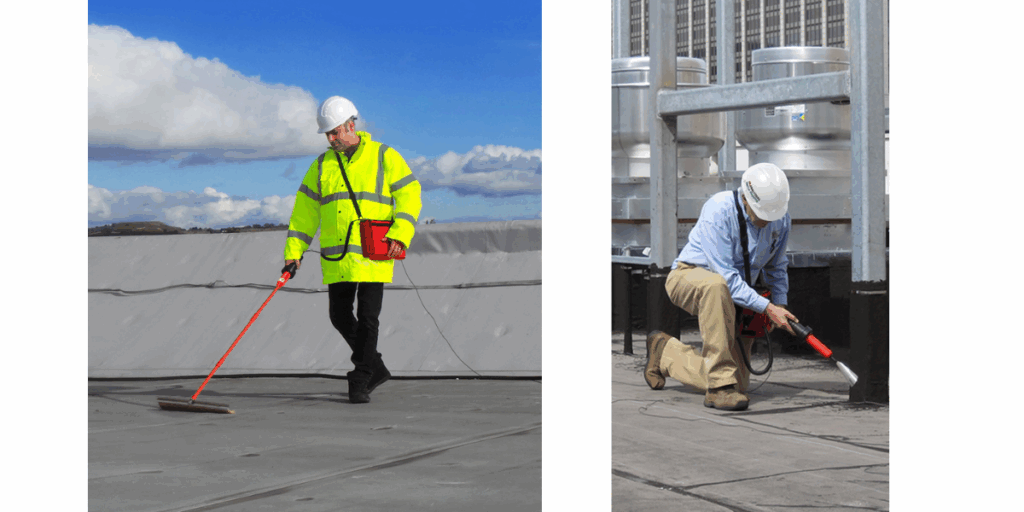

High Voltage Electronic Leak Detection (ELD), often referred to as “dry or spark testing,” involves sweeping an electrified brush across the surface of the membrane. The brush delivers a high-voltage (typically 5,000–12,000 volts DC), low-amperage current that’s entirely safe for the membrane, the structure, and the technician.

When the current encounters a breach in the membrane, it passes through to the conductive substrate or a grounding medium such as TruGround® Conductive Primer directly beneath the membrane. This triggers an audible alarm, allowing the technician to precisely locate and document the fault.

High Voltage ELD is a versatile and highly accurate testing method, particularly effective for:

While High Voltage ELD is a highly effective option, there are a few limitations to consider:

However, with most assemblies, High Voltage ELD delivers more complete coverage around drains, curbs, parapets, and flashings.

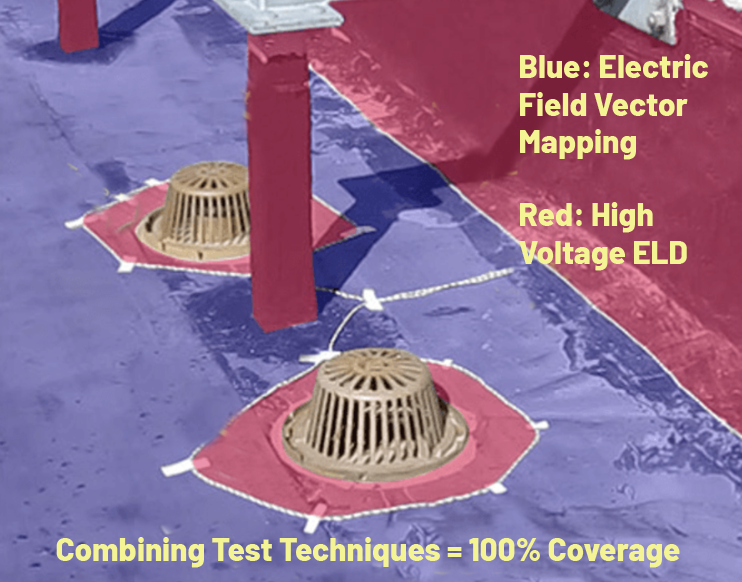

Every roof is different, and in many cases, Electric Field Vector Mapping alone won’t give you full coverage. Sometimes, the best way to ensure a thorough inspection across the entire membrane is to combine Electric Field Vector Mapping and High Voltage ELD.

ELD Fusion® utilizes both Electric Field Vector Mapping and High Voltage ELD to ensure 100% membrane coverage. Wet testing is used for the large sections of the field of the roof, while dry testing is used in places where wet testing struggles, such as at transitions, around drains and penetrations, or on vertical surfaces like curbs and parapet walls.

When technicians have access to both systems, they can apply the most effective method to each part of the assembly, even adjusting their approach in real time based on membrane type, the project’s history, and environmental conditions. By using each method where it works best, you get the most thorough and accurate picture of your roof’s integrity.

In addition, ELD Fusion testing ensures that a spec calling for Electric Field Vector Mapping is met while still ensuring that 100% coverage is achieved by adding High Voltage ELD.

Whether you're managing construction on a new installation, conducting quality assurance or integrity testing of a newly completed assembly, or performing leak investigations, choosing the right roof testing method is critical. And oftentimes, the best results come from combining multiple specialized approaches.

At IR Analyzers, we have found that a one-size-fits-all approach to roof testing can result in reduced coverage and missed breaches. Our technicians are experienced with applying the most effective method(s) based on your individual project’s history, assembly type, and site conditions.

We’ll evaluate your roof system and testing goals, walk you through your options, and recommend the best path forward—whether that’s dry testing, wet testing, or ELD Fusion® for full coverage. Have questions or want to schedule a consultation? Contact us today and we’ll help you get started.