Call Now (800) 879-1964

Your roof is a critical part of your building’s infrastructure. And like any complex system, it performs best when it’s regularly maintained. Without a clear maintenance plan, problems like breaches, hidden membrane damage, and drainage issues often go unnoticed until major repairs—or full replacement—are needed.

What makes it even more challenging? Many commercial and industrial roof failures begin silently. Water seeps in through minor breaches, flashing defects, or membrane punctures and spreads beneath the surface. By the time visible signs appear, structural damage is already underway.

A proactive roof maintenance plan is a long-term strategy that will help you:

In this guide, we’ll walk you through a comprehensive roof maintenance checklist to help you build your plan.

An effective maintenance plan should incorporate multiple layers of protection, including routine checks, non-destructive testing, drainage assessments, thorough documentation, and proactive repairs. Each element plays a role in protecting your investment and preventing costly surprises down the line.

Follow this checklist to develop your plan:

Debris buildup can block drainage paths, trap moisture, and accelerate membrane deterioration, especially at seams, penetrations, and flashings. Left unchecked, it leads to standing water, added structural load, and significant damage.

Make debris removal part of your regular maintenance plan. Focus on areas where material tends to collect, including:

Clearing these areas helps maintain proper water flow and improves the accuracy of any moisture or leak detection testing you conduct.

Spotting trouble early is key to preventing costly damage. Keep an eye out for these common warning signs during routine walkthroughs or inspections:

These indicators often point to hidden moisture or developing leaks and should prompt further investigation through non-destructive testing.

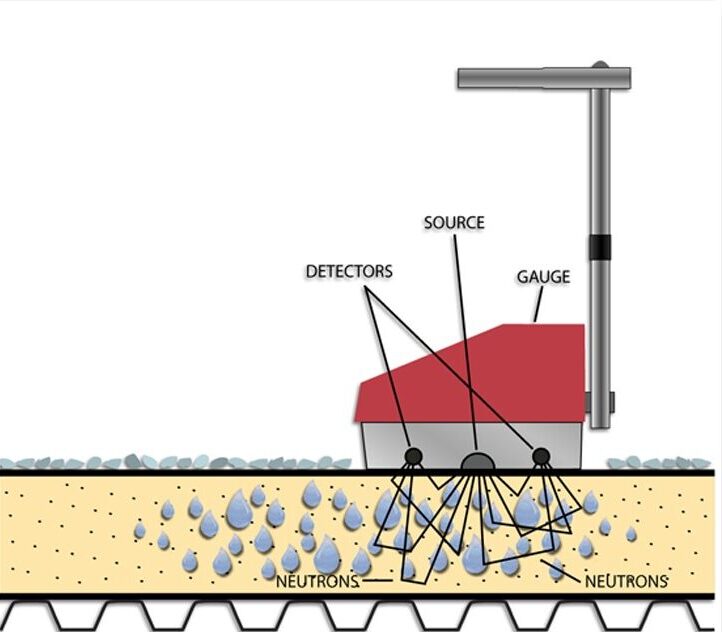

Trapped water beneath your roof membrane often causes the most damage and can't be spotted with visual checks alone. Using Roof Moisture Surveys and Electronic Leak Detection (ELD), you can identify issues beneath the surface and ensure a watertight membrane.

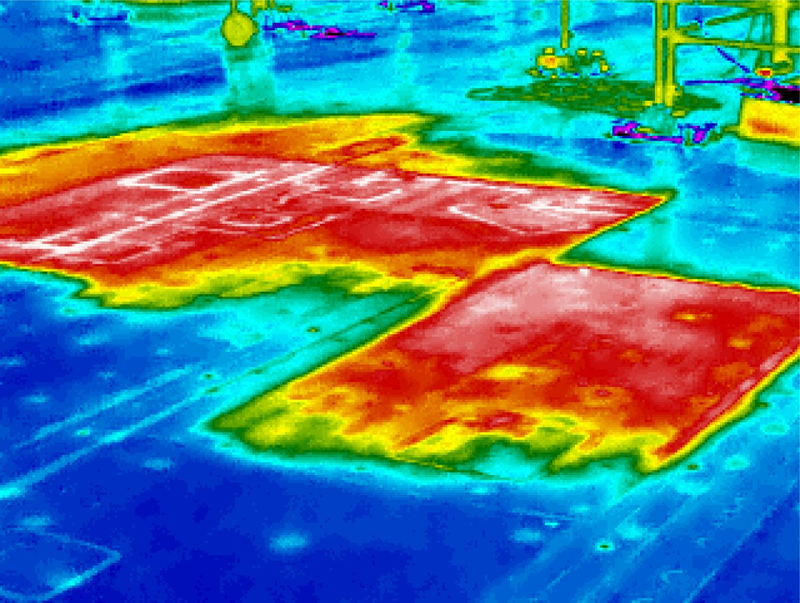

At IR Analyzers, we use three non-destructive methods to locate moisture invisible to the eye:

These methods comply with industry standards such as ASTM C1153, D7954, and ANSI/SPRI/RCI NT‑1. They are proven, reliable tools for targeting repairs and maximizing roof lifespan.

While moisture scans uncover hidden wet insulation before structural damage begins, ELD testing ensures a breach-free membrane at installation and is invaluable throughout the life of the roof. These testing methods can identify even the smallest breaches, including pinhole leaks, in both flat and vertical surfaces:

At IR Analyzers, we combine different testing methods based on a building’s roof type, system configuration, and specific concerns. We recommend this tailored approach for any roof maintenance plan to gain more comprehensive, accurate and actionable results.

Testing schedules can vary based on a building’s roof system type and needs; however, testing is generally recommended:

Consistent testing plays a vital role in preventative roof maintenance, allowing you to catch issues early, ensure the integrity of your structure, and maintain compliance.

Accurate documentation is a key part of any effective roof maintenance program. Consistent records help verify warranty compliance, support insurance claims, and provide a clear history of roof maintenance and performance over time.

Your documentation should include:

Staying organized makes it easier to track patterns, plan capital improvements, and respond quickly when issues arise.

Foot traffic is one of the most common and preventable causes of roof damage. Maintenance crews, HVAC contractors, and inspectors can unintentionally puncture membranes and negatively impact protective layers.

To reduce this risk:

Proactively managing roof access helps extend system life and ensures your commercial roof maintenance plan accounts for real-world wear and tear.

Even small issues, such as punctures, cracked sealants, or localized leaks, can compromise a roof system over time. Water intrusion spreads, insulation degrades, and structural elements weaken if left unaddressed.

Include regular follow-ups in your maintenance plan. Use moisture survey data and certified inspection reports to confirm repairs are holding and to catch any new problems early.

Even the best roof maintenance plan will fall short without clear accountability. Every task, whether it’s a routine check or advanced moisture testing, should have a designated owner.

Here’s how to structure responsibility effectively:

Outlining these roles in advance prevents confusion, ensures timely follow-through, and strengthens the overall success of your roof maintenance program.

No two commercial roofs are the same, which means your maintenance plan shouldn’t be either. Roof design, materials, regional climate, building use, and warranty requirements all influence what your plan should include and how frequently it should be updated.

For instance, an industrial roof maintenance plan for a manufacturing facility may require more frequent inspections due to constant rooftop equipment access and exposure to chemical exhaust. In contrast, an office building might focus more on seasonal weather checks and long-term membrane integrity.

To build an effective, customized commercial roof maintenance plan:

Tailoring your plan helps identify small issues before they become major disruptions, while also ensuring compliance, extending roof life, and protecting your budget.

A strong commercial or industrial roof maintenance plan is more than a checklist; it’s a strategy for reducing risk, extending system life, and preventing expensive failures before they start.

At IR Analyzers, we’re here to support that strategy. With decades of experience, certified reporting, and access to all non-destructive testing methods, we help contractors, consultants, and building owners stay ahead of potential failures.

Need help building your plan or verifying your roof’s condition? Contact us today, and we’ll help you determine the right testing approach to strengthen your maintenance program.