Call Now (800) 879-1964

If you're responsible for keeping infrastructure online, you already know the margin for error is razor-thin. A single unchecked humidity spike, an overloaded breaker, or a minor roof leak can snowball into substantial downtime and equipment damage.

Whether you're managing an enterprise facility, a fault-tolerant data hall, or overseeing infrastructure across multiple sites, the risks are the same and so are the blind spots. This guide covers practical maintenance strategies, overlooked failure points, and a focused approach to preventing the problems that slip through standard maintenance.

Most teams monitor climate conditions. Fewer ask why they keep drifting.

Power loads change, airflow gets disrupted, and building dynamics shift over time. Temperature, humidity, and airflow metrics offer early clues—not just about environment, but about the underlying stability of the entire space.

Staying within ASHRAE’s recommended range is table stakes. But even well-balanced systems can develop hot spots, inconsistent rack temperatures, or airflow blind spots that don’t show up in room-level monitoring. These aren’t always violations—they’re patterns that signal load imbalance, poor containment, or missed adjustments after equipment changes.

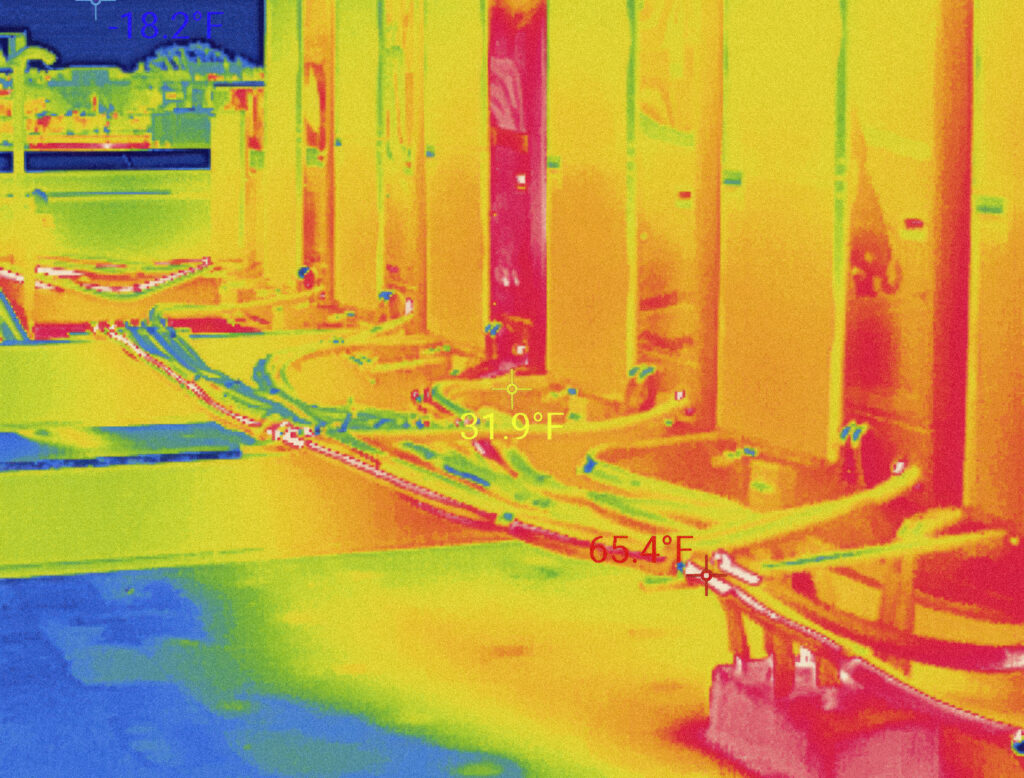

Rack-level infrared thermal scans and periodic cooling reviews do more than keep things compliant; they help you spot issues early and optimize before alarms ever go off.

ASHRAE recommends a relative humidity range of 40%–60% for Class A1 environments, but variability is often a bigger issue than the number itself.

Unexpected spikes or drops may indicate problems with containment, insulation, or even exposure to external weather. Dew point monitoring can help detect subtle changes, especially when relative humidity seems stable.

Airflow tends to degrade gradually—shifted tiles, tangled cables, and layout changes all affect balance over time.

Even with containment, you can’t assume airflow is working as intended without measurement. Periodic CFD analysis or airflow velocity checks can confirm that your cooling strategy is still aligned with real-world conditions.

Facilities infrastructure is often overlooked until failure hits. Roofing, insulation, and envelope integrity play a direct role in equipment safety and climate control, and they’re far more fragile than most teams realize.

Even a minor leak near a UPS or power distribution panel can cascade into widespread failure. In a landmark study by the Ponemon Institute, 35% of unplanned data center outages were caused by water incursion, from roof leaks to internal condensation.

And while technology has advanced, the fundamentals haven’t changed. According to the Uptime Institute’s 2022 Global Data Center Survey, nearly 80% of impactful outages were considered preventable, with better visibility, planning, and infrastructure oversight.

Annual visual roof inspections, Infrared Roof Moisture Scans, Electronic Leak Detection Testing, and post-storm testing are targeted, high-impact checks that often prevent larger failures.

A compromised building envelope can quietly undermine temperature control, humidity stability, and energy efficiency. Testing methods like blower door diagnostics and infrared imaging help detect air leaks, insulation gaps, and moisture vulnerabilities that compromise stability.

Rather than relying on a single test, most evaluations combine multiple techniques to assess both thermal and airflow performance. The goal is to identify invisible weaknesses before they turn into costly failures. Reference standards include ASTM E779 and ASTM C1060, which are widely used in building envelope diagnostics.

Some of the most damaging issues in a data center don’t make noise—they make heat. That’s where Infrared Electrical Inspection comes in. It’s one of the simplest ways to catch electrical problems early: overloaded breakers, loose connections, phase imbalances, and ventilation issues all show up clearly through a thermal lens.

Updated guidelines from NFPA 70B (2023) now recommend scanning all electrical equipment at least once a year. For systems with a history of failure or signs of wear, semiannual or even quarterly scans may be warranted, especially in mission-critical environments where uptime is non-negotiable.

In most well-run facilities, Infrared Electrical Inspections are included in regular preventive maintenance schedules and cover electrical panels, battery backup systems, and HVAC units. It’s fast, non-invasive, and often the first step in catching issues that could lead to serious downtime.

Even well-run teams fall into blind spots. These areas deserve tighter processes, not necessarily because they’re complex, but because they’re easily overlooked.

Cable mismanagement doesn’t just create clutter—it compromises airflow, complicates troubleshooting, and increases fire risk. Most modern data centers follow TIA-568 for structured cabling and BICSI 002 for layout, separation, and documentation—either explicitly or through vendor implementation.

Even if these standards are already in place, routine enforcement matters. Over time, expansions, patches, and personnel turnover can erode discipline. Periodic reviews help ensure that labeling, bundling, and cable paths remain consistent and support airflow rather than hinder it.

CRAC filters, UPS batteries, fans, patch cables—if you don’t track usage and shelf life, you risk scrambling during a failure. Maintain an up-to-date inventory of critical spares and test them on a fixed rotation.

Without detailed records, trends go unnoticed and audits become painful. Use centralized tools to log all inspections, Infrared Roof Moisture and Leak Detection Surveys, test results, and service history. Good documentation supports compliance, but more importantly, it supports decision-making.

While most teams handle the big-ticket items, it’s the routine tasks that quietly drift off schedule, especially when no one’s tracking them. The checklist below reinforces the essentials that help teams stay consistent, even when priorities shift.

| Frequency | Tasks |

| Daily | - Temperature and humidity verification- Alert status check |

| Weekly | - Airflow path inspection- Access control system review- Log file review |

| Monthly | - Generator load test- Fire suppression system check- Sensor calibration |

| Semi-Annual | - Roof inspection- Building envelope assessment |

| Annually | - Infrared scan of electrical and mechanical systems- Emergency response plan review |

This isn’t a full maintenance plan, but it covers the tasks most often overlooked, the ones that quietly lead to downtime. Stick to the rhythm, and your systems will tell you when something’s off before the situation escalates.

But even the most consistent internal routines can fail when roles aren’t clearly defined, and when vendors aren’t held accountable for their part in the equation.

No matter how well your systems are maintained, a lack of clear ownership can stall response times and expose you to unnecessary risk. In complex environments—especially those involving outside vendors or overlapping IT/facilities teams—responsibility gaps are one of the fastest ways small issues become major incidents.

Define ownership clearly:

Don't assume everyone already knows “who handles what.” Revisit the boundaries regularly—especially after staffing changes or contract transitions. During a critical event, ambiguity slows you down. Alignment speeds you up.

Outsourcing saves time—but only with strong oversight. Whether you're working with HVAC technicians, roofing contractors, or testing specialists, vendor performance is only as good as the structure around it.

Use clear scopes of work, define SLAs, and keep a detailed log of service visits and inspection outcomes. That includes documenting when they were on-site, what was tested, and what issues were identified.

Vendors that specialize in complex diagnostics, like Roof Moisture Surveys, Electronic Leak Detection, or Building Envelope Testing, can uncover risks your team may not have the tools or bandwidth to detect. Partners like IR Analyzers bring not only technical expertise but also the consistency and reporting discipline needed to support audits and internal reviews.

Failures rarely come out of nowhere. Often, they follow a trail of unchecked wear: a missed inspection, a cracked seal, a loose connection. These issues don’t always trigger alerts, but they build pressure until systems break down, sometimes without warning.

IR Analyzers focuses on risks that fall outside the scope of most vendor contracts by proactively targeting roof integrity issues, electrical weaknesses, and indicators of incipient envelope failure. Our professional Roof Moisture Surveys, Electronic Leak Detection Testing and Building Envelope Diagnostics help you identify problems that other monitoring systems weren’t designed to detect.

According to the Uptime Institute’s Annual Outage Analysis 2023, over 70% of major outages now cost over $100,000, and 25% exceed $1 million. Downtime is expensive. Prevention doesn’t have to be.

Want to make sure you’re not missing the early warning signs? Get in touch to schedule a consultation or learn more about how we help data centers stay ahead of avoidable failures.