About Our Electrical & Mechanical Inspections

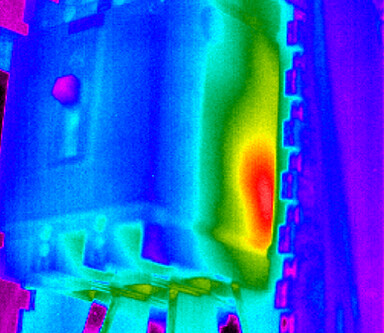

Electrical Inspections

- Pinpoints Hot Spots in Electrical Systems

- Reduces Down Time – Increases Profits

- Substantially Reduces Unscheduled Outages and Losses

- Reduces Electrical Energy Costs by Increasing Energy Efficiency

- Proactive, Predictive Approach – Avoids Unscheduled Maintenance

- Increases Efficiency in Electrical Maintenance Programs

You can pinpoint and repair electrical problems before they happen with our Electrical Inspections.

Reduce downtime and increase profits with an infrared electrical test.

Save time and money, call today for a free quote: 800-879-1964

Today’s facilities engineers are saving of millions of dollars every year with infrared electrical surveys. Periodic infrared electrical scans can substantially improve profitability and reduce your operating, testing and maintenance costs by:

- quickly pinpointing problems

- reducing downtime and equipment damage

- preventing catastrophic failures

- establishing repair priorities

- improving preventive maintenance efficiency

- testing under load to avoid costly shutdowns

In electrical systems, excessive heat is a sign of impending trouble.

High temperatures indicate excessive electrical resistance, failing components, ground faults, short circuits or other common problems in electric equipment that can lead to expensive or even catastrophic failures. Trying to find these incipient failures with visual and manual inspections is a costly, time-consuming process that may not locate the underlying problems.

Using cutting-edge infrared detection technology, our Certified Thermographers rapidly and accurately pinpoint the thermal anomalies that threaten the safety and reliability of your electrical systems.

Thousands of points can be tested in a single day. In a matter of hours, our electrical infrared testing can develop a complete catalog of the hidden thermal stresses in your operating equipment.

Because thermography is non-contact and nondestructive, there is no need to interrupt production or plan for costly shutdowns. Our thermographers inspect your equipment under normal loads and operating conditions, so you don’t have to disrupt your service and production schedules. By performing an infrared scan of your electrical system in ‘real time’ our inspections can help you understand the practical impacts of emerging component problems.

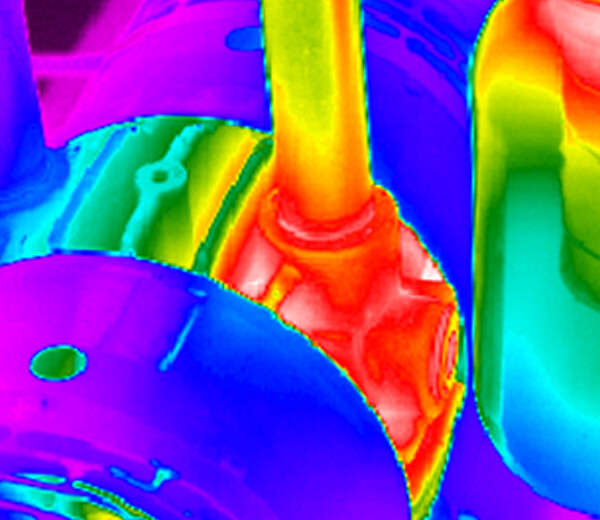

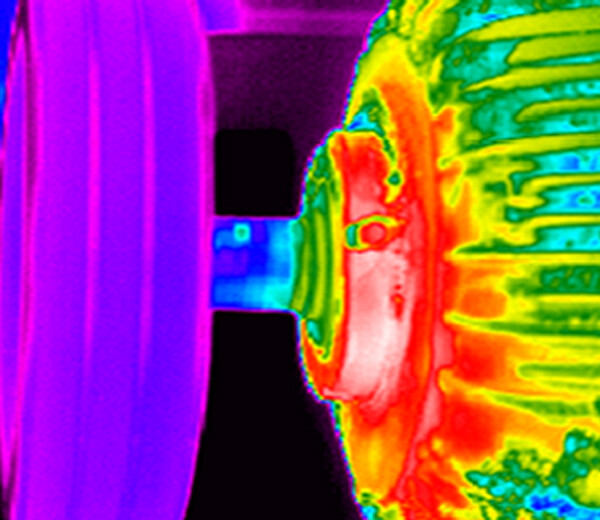

Mechanical Inspections

- Pinpoints Problems in Rotating Equipment

- Identifies Overheating Motors, Bearings, Couplings, Shafts, Belts, U-Joints…

- Targets Problems Due to Alignment, Overloading, Lubrication

- Substantially Reduces Risk of Catastrophic Equipment Failure

- Proactive, Predictive Approach Avoids Unscheduled Maintenance

- Lowers Costs by Reducing Downtime and Preventive Maintenance Expense

Your mechanical systems have hidden problems that can be pinpointed and prioritized with our infrared surveys.

Reduce downtime and increase profits with nondestructive testing. Call today for a free quote: 800-879-1964

Today’s facilities engineers are saving of millions of dollars every year with infrared mechanical inspections. Our professional infrared mechanical scans can substantially improve profitability and reduce your operating, testing and maintenance costs by:

- quickly pinpointing problems

- reducing downtime and equipment damage

- preventing catastrophic failures

- establishing repair priorities

- improving preventive maintenance efficiency

- testing under load to avoid costly shutdowns

In mechanical systems, excessive heat is also a sign of impending trouble.

High temperatures indicate excessive electrical resistance, worn components, lubrication failure, or other common problems that can lead to expensive or even catastrophic failures. Trying to find these incipient failures with visual and manual inspections is a costly, time-consuming process that may not locate the underlying problems.

Using cutting-edge infrared detection technology, our Certified Thermographers rapidly and accurately pinpoint the thermal anomalies that threaten the safety and reliability of your mechanical equipment.

Thousands of points can be inspected in a single day. In a matter of hours, our infrared tests can develop a complete catalog of the hidden thermal stresses in your operating equipment.

Because thermography is non-contact and non-destructive, there is no need to interrupt production or plan for costly shutdowns. Our thermographers inspect your equipment under normal loads and operating conditions, so you don’t have to disrupt your service and production schedules. By testing the operation of your systems in ‘real time’ our inspections can help you understand the practical impacts of emerging component problems.