High Voltage Leak Detection

About High Voltage Electronic Leak Detection

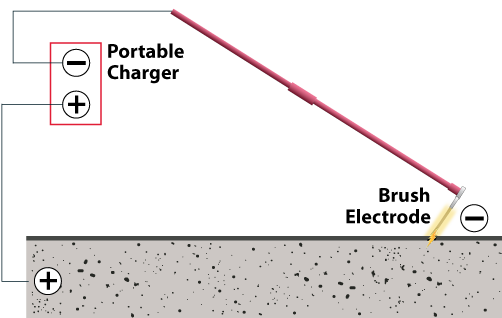

High Voltage ELD is performed on dry horizontal and/or vertical surfaces using a very small current at relatively high voltage for safe and reliable testing. One lead from the portable current generator (charger) is grounded to the roof or structural deck (either metal or concrete). The other lead is attached to one of several available electrode brushes made with highly conductive metal bristles. As the technician “sweeps” the brush electrode over the surface of the membrane or flashing, electricity will flow through any breach or gap, completing an electrical circuit between the brush and the deck. Where there are no faults in the waterproofing system, the membrane or flashing acts as an insulator and prevents the flow of current to the deck.

High Voltage ELD vs Low Voltage Vector Mapping: Both High Voltage ELD and Low Voltage Vector Mapping can be employed on most roofing and waterproofing membranes. However, because the High Voltage brush sensor must make direct contact with the membrane, roofs with overburden (vegetation, pavers, ballast, etc.) must be tested with Low Voltage Vector Mapping. Neither method can reliably inspect black EPDM membranes, which contain carbon black and are therefore electrically conductive.

High Voltage testing is often faster, simpler and less expensive than Low Voltage Vector Mapping, which requires more setup as well as constant wetting of the membrane. The interpretive nature of Low Voltage testing can require more inspection time, particularly if multiple breaches are present. Both techniques are safe, cost-effective and highly reliable, allowing problem areas to be quickly marked, repaired, and re-tested.

High Voltage ELD benefits:

- Pinpoints membrane defects for efficient repair

- Repairs can be immediately re-tested

- Detects all breaches, even pinhole and capillary action leaks

- Sloped roof systems and flashings can be efficiently tested

- Enables direct (non-interpretive) detection of membrane breaches

- Suitable for both horizontal and vertical surfaces

- Less expensive, faster, safer, and more reliable than flood testing

High Voltage ELD applications:

- Insulated and non-insulated low-slope roof systems (excluding

metal-coated and carbon black EPDM membranes) - Flashings and parapet walls

- Green roofs before placement of overburden

- Plaza decks

- Quality Assurance

- Warranty Verification

- Membrane integrity testing

- Pools, parking garages, liners

- Other waterproofing membranes & coatings